As a faculty of the Earth Sciences Department at Goa University, Dr. A.G Chachadi wanted to develop a facility to harvest rainwater and recharge groundwater at the campus at Taleigao Plateau. He wanted to showcase rainwater harvesting within the campus and also spread awareness on the benefits of doing it.

Initial calculations showed that groundwater at the University campus was pumped out at a rate of about 250 m3 per day from all the 7 operational borewells for about 300 days in a year. That totals about 75000 m3 of groundwater every year. He did a simple calculation to understand how much rainwater could be harvested before implementing the system.

- Total drainage area contributing surface runoff = 30000 m2

- Daily average monsoon rainfall in the area = 0.02m/day

- Surface runoff collected per day (50% of rainfall) = 300m3

- Estimated recharge to sub-surface thru borewell = 250m3

- Ratio of aquifer recharge to runoff collection= 250/300 = 83%

- Amount lost due to seepages, evapo-transpiration and other factors = 17%

How does the system work?

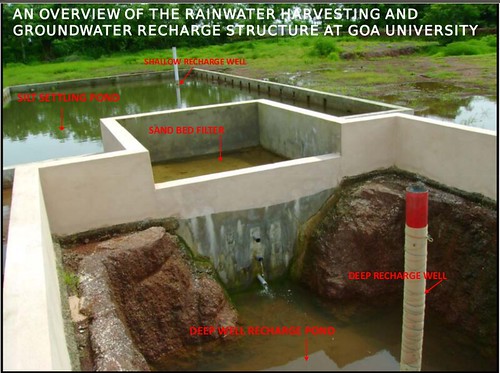

At the site, the rainwater falling on the ground is collected into a 70m x 50m size depression using gravity flow. The structure has three parts of which the first part with a size of 20m x 10m and depth of 2m allows the suspended solids to settle down.

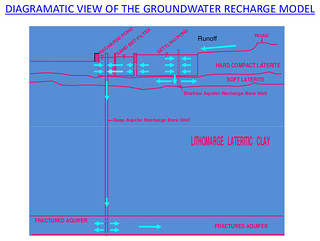

The clear water is then allowed to flow through using gravity into a sand bed filter with dimensions of 3m x 3m x 3m. The final part of the structure has a 90m deep borewell around which 3m x 3m x 3m trench has been created to allow the clear water to stand around. This 3m column of water creates adequate pressure to push the water through the slotted borewell casing into the borewell and the aquifer at depth. The injected water into the aquifer slowly percolates into the surrounding areas in the subsurface and hence enhances the storage of groundwater.

As the velocity of groundwater is normally very slow, it takes a long time for the injected water to reach the pumping wells located at about 400m to 600m away from the recharge site. During this slow movement, the injected water undergoes quality changes due to its interaction with the surrounding rock matrix. This recharged water is pumped back during the summer months from the existing borewells around the recharging site.

Advantages to harvesting surface runoff

- It reduces significant evaporation losses and saves water for harvesting over a long periods.

- The storage in the trench allows a longer time for the water to percolate into the subsoil.

- Over a period of years, the village wells located in the periphery of the plateau would also receive recharged water, which will alleviate some of their water scarcity problems.

- Storing rainwater in the subsurface is safe and free from pollutants as it is protected by overlying geological strata.

The rainwater harvesting structures built in the campus have minimum maintenance activities and recurring costs. The various annual maintenance activities include:

- Removing grasses and weeds and general cleaning in and around the surface water harvesting structure.

- Spraying of bleaching powder around the structure to avert any unwanted bio-contaminants entering along with the first runoff water.

- Closing the outlet pipe caps before the onset of rains so as to keep away the first rainwater from entering into the recharge well. This water is allowed to evaporate while some of it seeps down through the pit bottom.

- Checking the water for bacteria e-coli before recharging.

- Cleaning out the green algae that forms during the monsoons in the recharge trench. This needs to be physically removed and bleaching powder added. Cleaning out the netlon mesh wrapped around the recharge well casing now and then so that there are no obstructions to the entry of water into the well.

- Removing and replacing the sand in the filter compartment every third year with new sand of mixed size.

- Flushing the recharging bore well every fifth year to remove internal clogging so that adequate recharge rates are maintained.

- Flushing out the roof water harvesting site of the first rainwater flow by closing the valves provided at the ground levels of the buildings.

- Cleaning thoroughly and flushing out the storage tank through an outlet pipe provided. The bleaching powder should be sprayed throughout the bottom of the storage tank soon after the cleaning.

- Opening the water inlet valves so that the roof water comes into the storage tank. At the same time the outlet valves allowing tank water into the bore wells should also be opened fully.

- Periodically locking and inspecting the tank to ensure the safety and other related aspects of the structure.

rainwater_harvesting_for_aquifer_storage_recovery.pdf

rainwater_harvesting_for_aquifer_storage_recovery.pdf